In Medieval times, the Cinque Port of Sandwich was a bustling seaport for ships and troops crossing the English Channel and then sailing on return to London. It was a mustering base for the 100 years’ war between England and France. There would always have been a large number of ships moored by the Quay, most of them would have been cogs.

The cog was a single mast, round bottom vessel that was built to be a merchant ship but, at times of war, converted into a fighting ship. The castles were added fore and aft and the long bow archers would create a formidable fire power.

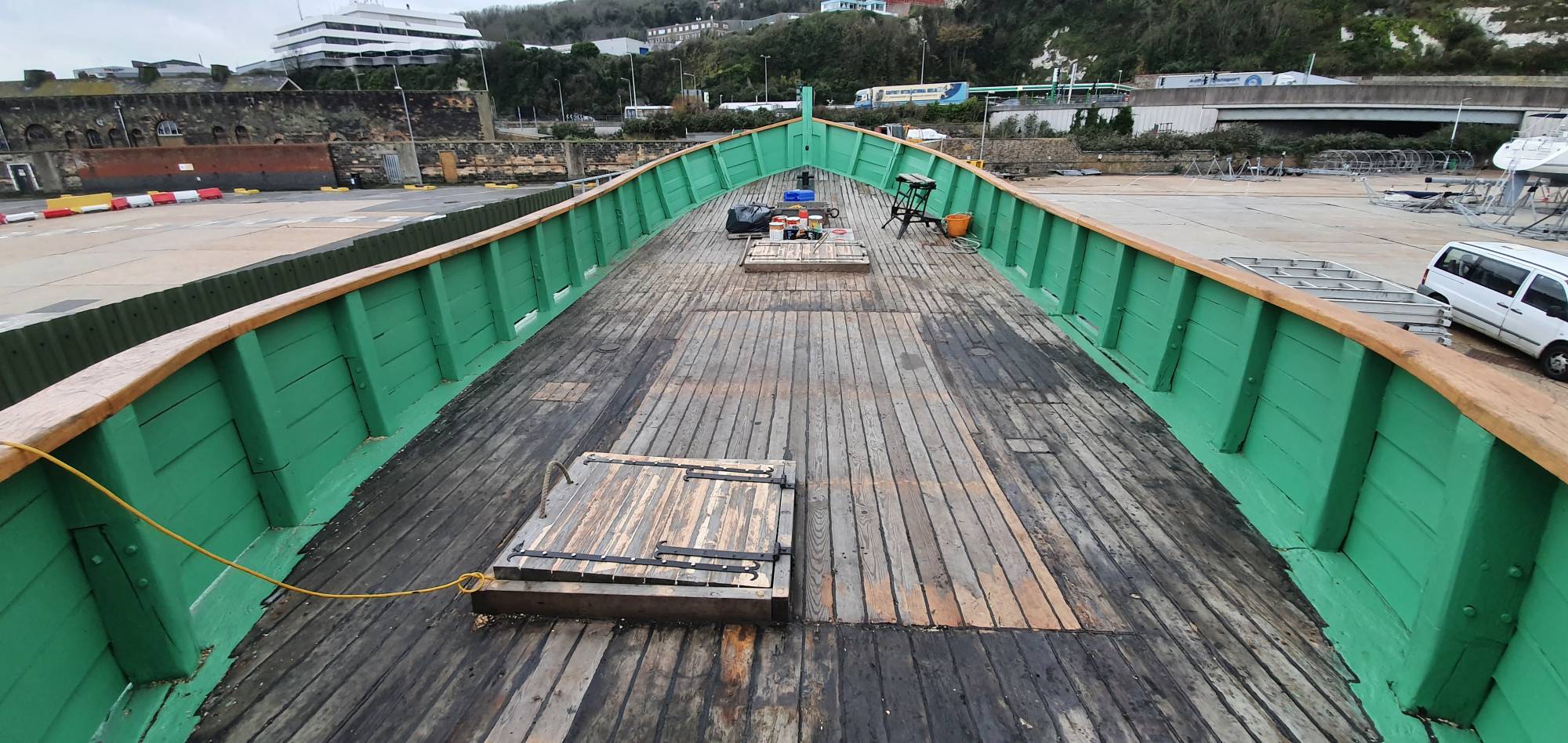

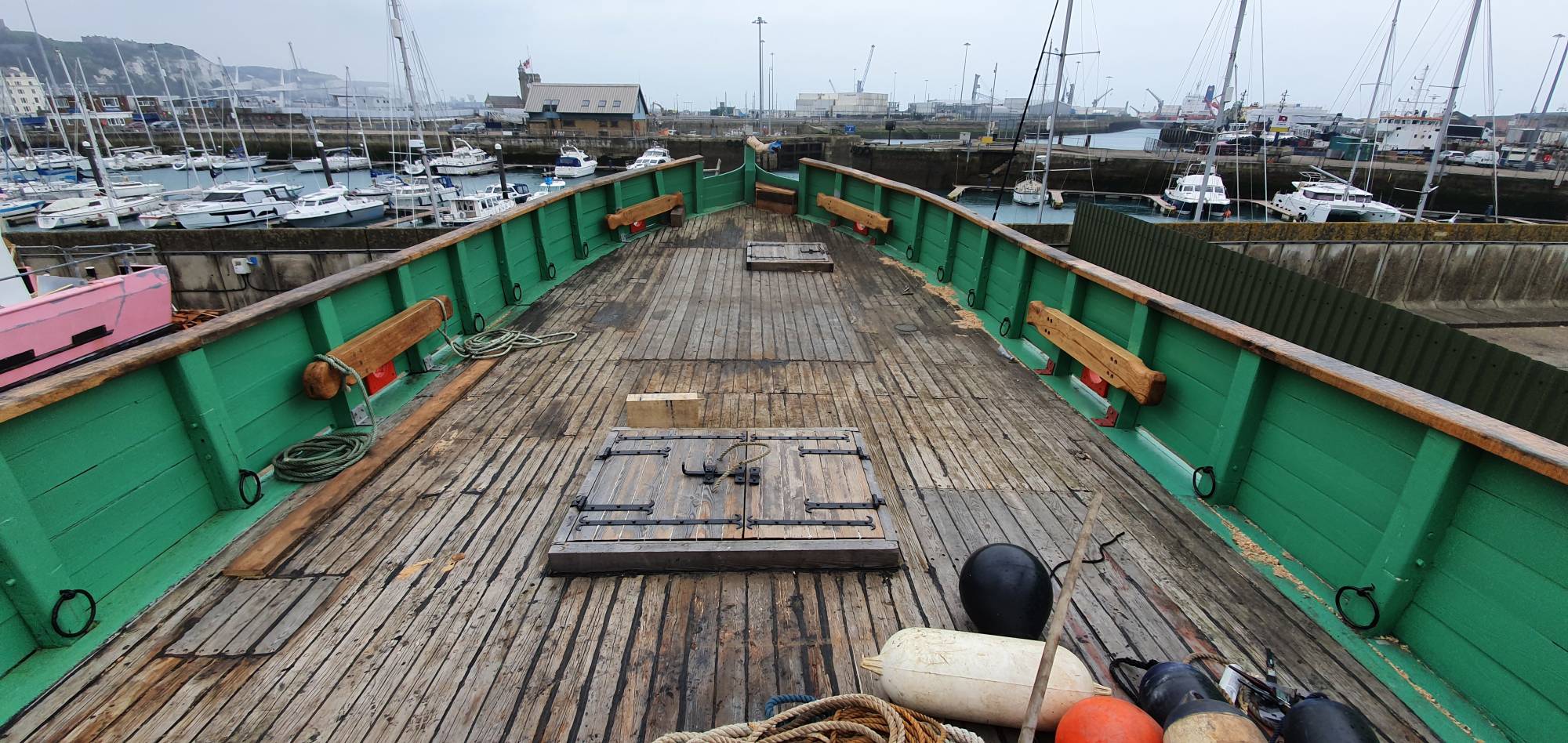

It’s hard to believe that there is no example of a medieval cog on display anywhere in England. Our project is to create a replica, a faithful reconstruction of what a medium sized 50ft long cog with a 40 ft mast would have looked like. We have bought a seaworthy, solid wooden hull built with traditional methods. We will add the castles, then the mast, sail and rigging and moor it on the river close to the Medieval Centre. It will look most impressive and add something quite special to the Quay side.

This exciting project is now well under way. The hull has been brought from Plymouth to Dover Docks, and renovation has started. We will bring it to sandwich just as soon as we can, when there will be a great opportunity for volunteers to help us work on it and turn it into a life sized cog, to be called the Nicholas.

** The Nicholas progress report **

Saturday 29th May 2021 the Nicholas arrives in Sandwich towed to her permanent home on the Quayside by Richborough Marine services.

Work immediately started on the deck and hatches with any deck beams that had been identified as needing replacing being removed and new beams cut and shaped ready for refitting. Hatches were caulked and pitch poured in the seams to make watertight.

The Windlass

wood sourced locally for the windlass spindle has been carved to sit in the windlass frames which will be mounted on the deck to lift the sail to the top of the mast. The lower parts of the windlass frames have been cut to size and ready for test fitting on the deck, steel braces, brackets and a ratchet mechanism has been made on the forge and fitted to the windlass.

The Capstan

The Capstan is made from one single piece of ash approximately 3.5 m long, it will rest in a large oak support mounted just above the keel and will rise up through the deck. It will mainly be used for lifting the anchors.

Two running surfaces have been carved on the capstan spindle, one at the very bottom which allows the spindle to turn in a steel socket with a ratchet mechanism on the oak bearer mounted just above the keel and the second is carved at deck level keeps the capstan sitting true and allows it to turn smoothly in the oak collar. Four square sockets have been carved to take the oak levers for turning the capstan. Along with the steel socket and ratchet, three steel bands made on the centres forge have been fitted to keep the spindle from splitting.

The Anchor

The first of two anchors being made for the Nicholas, the stock is made from oak which is held in place around the steel shank using long steel rivets and bands all made on the forge.